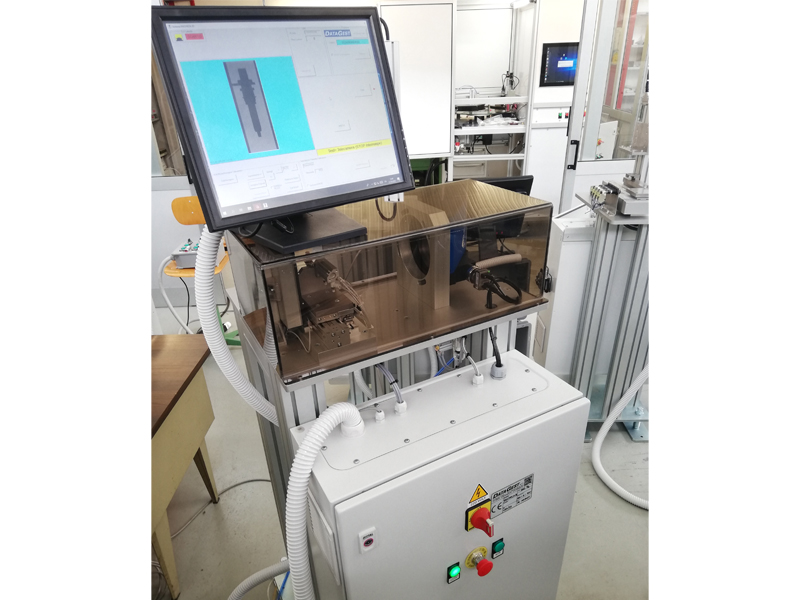

The DGCHECK system is a control station that performs contact/non-contact testing and returns a GO/NOGO signal

The DGCHECK system accepts the piece from a robot, which is at the service of, for example, a lathe, carries out the check and takes it back outside, generating the appropriate signals.

There are two variants:

With camera for dimensional measurement with 80x50mm field of view

Camera, telecentric optics and collimated back light illuminator are provided.

Field of view: 80 x 30 mm

Available parameters: up to 30 independent, repeatability of ± 2µm.With screwdriver for thread control. Both the angular travel performed and the absolute Z position of the pad are inspected by checking the final position.

Programmable : Test torque, screwing speed, unscrewing torque, final position reached